|

Wuhan Hankou Furnace Co.,Ltd

|

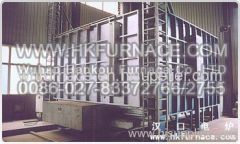

Pit al-alloy Ageing Furnace

| Place of Origin: | Hubei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

RJ3 series Pit al-alloy Ageing Furnace is a sort of energy-saving cycle operation Aging Furnace

RJ3 series Pit al-alloy Ageing Furnace is a sort of energy-saving cycle operation Aging Furnace.It is used for ageing heat treatment of Alloy Die Casting, Aluminum profile, piston and other aluminum alloy parts under the high uniform temperature station. Products implement China's aviation industry military standards GJB509-98-88. When you use our products in aerospace, aviation aircraft manufacturing industry, users should choose the electric furnace high-precision temperature control procedures microcomputer counters.

Structure description:

RJ2 series of high temperature pit furance structure, the shell are welded by steel plate and steel cylindrical furnace, all of them are used in all enclosed welding. Lining using ultra-light 0.6g/cm3 energy-saving vacuum insulation ball refractory brick building. Lining home with the furnace shell laminated aluminum mat acid insulation, insulation powder expansive space filled. Resistance silk used 0Cr25Al5 high resistance alloy wire around the spire installed in the furnace of dormant Wire and Bricks. Lid using manual or electric movements. There is a stainless steel furnace loading basket in the furnace hearth. Furnace cover is operated by manual bar, large-scale cover is operated by electrical variable speed machine. In order to make uniform heating workpiece, the lids are installed with heat-resistant stainless steel shaft and the blower hot air circulating fan, the heating process of the workpiece, hot air in the Al-alloy Ageing Furnace cycles up and down in a high speed to ensure workpiece to be heated uniformly.

More detailed technical___directly sale Tel:0086027-83372766 83372755 8613807177084

Technical parameters:

| Parameters Name | Unit | Model | ||||

| RJ3-20-5 | RJ3-30-5 | RJ3-45-5 | RJ3-60-5 | |||

| Rating Power | KW | 20 | 30 | 45 | 60 | |

| Rating Voltage | V | 380 | 380 | 380 | 380 | |

| Highest Temperature | ℃ | 500 | 500 | 500 | 500 | |

| Working Temperature | ℃ | 500 | 500 | 500 | 500 | |

| Phase Number | 3 | 3 | 3 | 3 | ||

| Hearth size | Dia. | mm | Φ500 | Φ700 | Φ800 | Φ1000 |

| Height | mm | 650 | 900 | 1100 | 1300 | |

| heating element | Y | Y | Y | |||

| heating-up time | h | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | |

| lose power | KW | ≤7 | ≤11 | ≤15 | ≤19 | |

| control accuracy | ℃ | ±1 | ±1 | ±1 | ±1 | |

| niformity | ℃ | ±5 | ±5 | ±5 | ±5 | |

| Maximum Loading | Kg | 250 | 500 | 800 | 1200 | |

| Weight | Kg | 1800 | 2600 | 3100 | 4000 | |

.gif)